Close

Paper Pulp

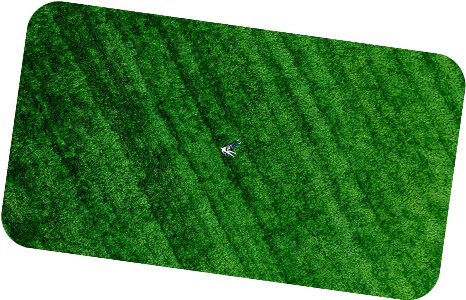

Paper manufacturing requires strong, flexible fibers and efficient drainage to achieve high-quality end products and optimize production.

Bleaching is one of the most chemical-intensive steps in pulp production, traditionally relying on chlorine-based chemicals that impact both cost and the environment.

Recycling paper is crucial for sustainability, but removing ink from wastepaper without damaging fibers can be challenging.

Microbial slime and organic deposits are major challenges in paper and pulp mills, causing equipment fouling, reduced efficiency, and frequent downtime

Pitch and stickies, originating from natural wood resins, recycled paper, adhesives, and coating residues, are persistent problems in paper mills.

Recycled fibers often face color contamination and reduced brightness due to residual dyes, inks, and organic impurities.

Starch plays a critical role in paper sizing and coating applications, improving paper strength, printability, and surface properties.

Enzymes such as xylanases reduce the need for harsh bleaching chemicals by breaking down hemicellulose and residual lignin in pulp. This improves pulp brightness and quality while lowering chlorine and peroxide consumption. As a result, mills achieve whiter, cleaner pulp with reduced environmental impact and lower operating costs.

Enzymes like cellulases and hemicellulases modify fiber surfaces, improving fiber bonding and refining efficiency. This leads to improved paper strength, smoother texture, and better printability while reducing energy requirements in mechanical refining. Enzymatic treatment ensures more uniform fiber properties, delivering consistent product quality.

In paper recycling, enzymes assist in efficient ink removal from recovered paper fibers, improving pulp cleanliness and brightness. Enzymatic deinking reduces the need for aggressive chemicals and high-temperature processes, lowering energy consumption and chemical waste. This supports sustainable recycling practices and extends fiber life for higher-quality recycled paper.

By replacing or reducing chemical inputs and energy use, enzymes help paper mills lower effluent load and greenhouse gas emissions. Enzymatic processes minimize fiber damage, reduce wastewater treatment costs, and enable eco-friendly paper production. This supports compliance with environmental regulations while achieving long-term cost savings and enhanced operational efficiency.